BPI ZAP SCREWLOK

BAR-TO-BAR mechanical butt splice. Zap Screwlok® Type 2 Series or Epoxy Series or ‘SL' Series

Mechanical butt splices shall be the tension-compression shear screw and wedge coupling sleeve type, with smooth converging sides and cone-pointed hex-head screws, to develop a strength in the bar equal to [state strength requirements].

BAR-TO-BAR mechanical lap splice. Double Barrel Zap Screwlok®

Mechanical lap splices shall be the shear screw and double wedge coupling sleeve type, with converging sides and cone-pointed hex-head screws opposite the wedges.

BAR-TO STRUCTURAL STEEL. Zap Screwlok® Structural Connectors

Bar-to-structural steel connections shall be the shear screw and wedge weldable connector type with smooth converging sides,

cone-pointed hex-head screws and weld bevels inclined 30-degrees to the rebar axis.

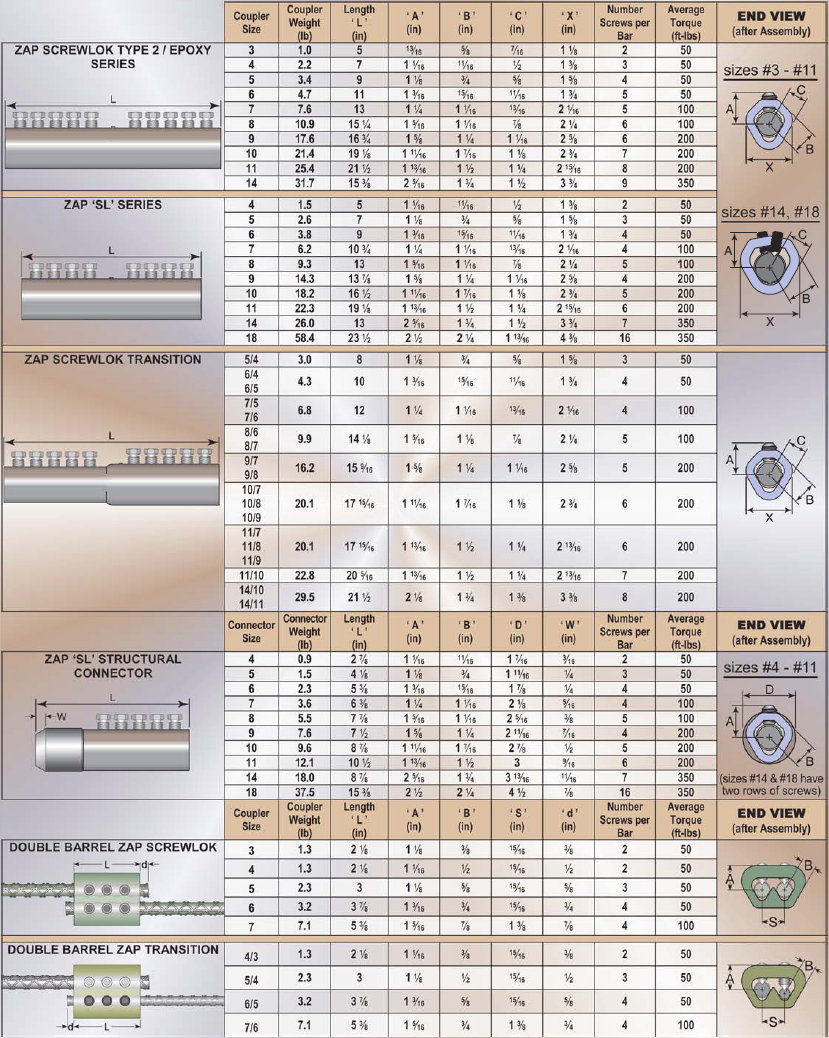

Dimensions and product references

Applications

FIELD SPLICE OPTIONS FOR YOUR PROJECTS

ZAP SCREWLOK ‘SL' SERIES

SHEAR SCREW AND WEDGE MECHANICAL SPLICE COUPLING SLEEVE

• ACI 318 Chapter 12 FULL MECHANICAL SPLICE- Develops in tension or compression, as required, at least 1.25 fy of the bar, ASTM A 615 black deformed Grade 60.

• COMMERCIAL APPLICATIONS- In accordance with Building Code Requirements for Structural Concrete, product is used in columns, beams, walls, mats, tanks, condominiums.

• SUPERIOR TO ALL TENSION LAP SPLICES- Strength is independent of surrounding concrete and cover. Takes up less space than rebar lap. Replaces lap splice classes A, B, or C.

• COMPACT DESIGN- Shorter than Type 2 series-fewer screws- less room needed - faster installation time- ideal for hard-to-reach places.

• FOR STANDARD REINFORCING BARS- ASTM A 615, ASTM A 996 and equal black deformed bars- exceeds 125% x specified yield, fy, Grades 40, 50, and 60.

ZAP SCREWLOK TYPE 2 SERIES

SHEAR SCREW AND WEDGE MECHANICAL SPLICE COUPLING SLEEVE

• TYPE 2 SPLICE- ACI 318 Chapter 21 and International Building Code. ICC ES Evaluation

Report ER-5461. Exceeds specified tensile strength (150% x fy) ASTM A 706 / A615 black deformed bars.

• SEIMIS LOADING- Withstands plastic strain excursions to 5 x rebar yield strain value and stress

Reversals in accordance with ICC Acceptance Criteria AC-133.

• NEW CONSTRUCTION or RENOCATION / REPAIR- Suited for butt-splicing bars new-to-new

Or new-to-old. Tested with Grades 30,33,40 and 50, square and round, to 1.25 fy.

• GRADE 75 BARS*- Exceeds 125% x specified yield black ASTM A 615 Grade 75 and capable of developing 100,00 psi, the specified tensile strength of Grade 75.

• CALTRANS "SERVICE" APPROVED- Meets slip test 670 & capable of exceeding 80,000 psi,

The specified tensile strength of black deformed bars ASTM A 706. Not classified as Caltrans "Ultimate."

• CONVENIENCE- Field installed- No specialized installation equipment- No special bar end preparation

Thread cutting- Easy visual inspection. For bars #3-14 (Dia. 10-43mm).

*Zap Screwlok Type 2 Series is not suitable for use with ASTM A 1035 Grade 100/120 MMFX bars or

"Dual-Certified" Grade 75/100, grade 80/100 bars or any variation thereof. Contact BPI for special Zaps.

ZAP SCREWLOK EPOXY SERIES

SHEAR SCREW AND WEDGE MECHANICAL SPLICE COUPLING SLEEVE

• ASSHTO and DOT- Exceeds 125% x specified yield (fy) per AASHTO Standard Specifications for Highway Bridges (17th Ed). Also exceeds 135% x Grade 60 bar (81,000 psi).

• PURPOSE- For butt-splicing epoxy coated bars that comply with AASHTO specifications and the coating requirements of ASTM A 775 Grade 60.

• APPLICATIONS- Widely used on bridge decks, and parking garages susceptible to salt induced damage. Other adverse conditions include wastewater treatment and chemical plants.

• CYCLIC LOADING- Qualified to DOT protocols including 100 cycles 5% fy to 90% fy in tension and 10,000 cycles stress reversal from 25,000 psi tension to 25,000 psi in compression.

• HIGH FATIGUE STRENTH- Pre-qualified to '18 ski' stress-range by testing for more than 1 million cycles of load.

• CONVENIENCE- Field installed- No specialized installation equipment- No bar end preparation or thread cutting- Easy visual inspection.

ZAP SCREWLOK TRANSITIONS

SHEAR SCREW AND WEDGE MECHANICAL SPLICE COUPLING SLEEVE

• PURPOSE- For butt-splicing bars of different sizes, such as 11-to-10, 11-to-9 and so on - -or for connecting bars of different configurations such as 1"-square-to-#9.

• APPLICATIONS- Columns, Walls, Piers, Caissons, parking Garages, High Rise Buildings- usually vertical bars.

• SIMPLE DESIGN- One piece device with converging sides for wedging of different bar sizes- Made from seamless shaped tubing with no welds- Includes center stop.

• TYPE 2 SPLICE- ACI 318 Chapter 21 Seismic Design and International Building Code. Develops specified tensile strength of black smaller bars ASTM A 706 or A 615.

• SEISMIC LOADING- Withstands plastic strain excursions to 5x rebar yield strain value and stress reversals in accordance with ICC Acceptance Criteria AC-133.

• CONVENIENCE- Field installed- No specialized installation equipment- No special bar end preparation or thread cutting- Easy visual inspection.

DOUBLE BARREL ZAP SCREWLOK

SHEAR SCREW AND DOUBLE WEDGE MECHANICAL LAP SPLICE

• MECHANICAL LAP SPLICE- ACI 318 Chapter 12- Develops in tension or compression, as required, at least 1.25 fy of the bar, ASTM A 615 black deformed Grade 60.

• APPLICATIONS- In accordance with Building Code Requirements for Structural Concrete, used to widen bridges, slab repair, to connect hoop bars and in piles to terminate spirals.

• SUPERIOR TO ALL TENSION LAP SPLICES- Eliminates hard-to-predict nature of lap splices-especially long epoxy bar laps- Positive connection instead of reliance on concrete.

• COMPACT DESIGN- Shorter than mechanical butt-splices and significantly shorter than lap splices- less room needed- ideal for many repair applications and construction joints.

• DOT PROJECTS and COATED BARS- Exceeds 125% fy Grade 60 when installed directly over epoxy coated ASTM A 775 bars or galvanized ASTM A 767 bars.

• CONENIENCE- Field installed- No specialized installation equipment- No special bar end preparation or thread cutting- Easy visual inspection. For bars #3-7 (Dia. 10-22mm).

DOUBLE BARREL ZAP TRANSITION

SHEAR SCREW AND DOUBLE WEDGE MECHANICAL LAP SPLICE

• PURPOSE- For mechanical lap splicing bars of different sizes, such as 6-to-5, 5-to-4, and so on- or for connecting bars of different types such as old to new.

• APPLICATIONS- Bridges widening, slab repairs, hoop bars, closure pours- use in accordance with Building Code Requirements for Structural Concrete.

• SIMPLE DESIGN- One piece device with converging sides for wedging of different bar sizes- manufactured as ductile casting with no welds.

• FOR STANDARD REINFORCING BARS- ASTM A 615, ASTM A 706, ASTM A 996, ASTM A 775 OR ASTM A 767 bars and equivalent deformed bars.

• PERFORMANCE- Develops in tension or compression, as required, at least 1.25 fy of the smaller bar.

• CONVENIENCE- Field installed- No specialized installation equipment- No special bar end preparation or thread cutting- Easy visual inspection.

ZAP STRUCTURAL CONNECTORS

SHEAR SCREW AND WEDGE WELDABLE CONNCECTOR

• STRENGTH RATING- Has capacity to exceed a minimum joint strength of 75,000 psi measured in the rebar, equal to 1.25 fy Grade 60.

• COMPATIBILTY- For use with black ASTM A 615 Grade 60 or ASTM A 706. Has capacity to exceed 1.25 fy in all cases.

• VERSATILITY- For attachment of reinforcing bars to plates, structural steel shapes or for creating headed anchorage. Shop or field weldable, before or after bar placement.

• CERTIFIED LOW CARBON STEEL- Meets low carbon chemistry AISI Grade 1018 and/or 1026. Mill certified analysis for each heat lot of steel available.

• WELDING BEVELS- For full penetrations, provided for greater strength, convenience and quality assurance.

• LESS WELD STRESS- Compared direct butt welds because outside diameter of structural connector is larger than the reinforcing bar so the weld area is disposed over greater length.

Features

When making splices between fixed points, a coupler sleeve without a center stop can be slipped entirely onto one bar and subsequently repositioned over the two bar ends being spliced.

Mechanical butt splices and connectors are available for reinforcing bar sizes No. 3 through 18 (dia. 10 through 57mm)

per BPI's Dimensions and Data charts. Transition splices are used to connect rebars of different sizes.

Mechanical lap splices are available for bar sizes No. 3 though 7 (dia. 10 through 22mm).

Headed Anchorage suitable for Grade 60 reinforcing can be created by welding Zap Structural Connectors and structural steel plates*. For simplicity, locally-sourced plate that has been cut square has a cross sectional area equal to 10-times the nominal area of reinforcing bar will be more than adequate for many applications; but other sizes and shapes of plate can be attached to suit structural demands.

Benefits

Benefits to using ZAP SCREWLOK® include positive mechanical splicing, choices for Type 1 Type 2 applications, splices for black or galvanized or epoxy coated bars, easy visual inspection, no specialized equipment, minimal clearance requirements and positive center-stop. Zap SCREWLOK® is ideal in remote areas and tight access areas; it is suitable for new construction repair or retrofit and compatible with sheared, flame-cut or saw-cut bars.

Function

Force from the screws causes rebar deformations to interlock within the coupler wedge. At the same time, the screws embed themselves into the rebar surface and then the heads TWIST OFF.

During mechanical splice assembly, as screws are tightened, they embed themselves into the rebar surface and then the heads twist off at a prescribed tightening torque. Force from the screws causes rebar deformations to interlock within the coupler wedge. The DUAL mechanical action, results in a full positive connection for transferring tension or compression forces from bar-to-bar. Screws can be tightened using suitable impact wrenches or hand-held ratchet wrenches. Linear alignment is preserved across the splice by using reinforcing bars with straight ends and securing the continuation bar in the desired position at the time of assembly.

Works carried out

- Agora Ciudad de las Ciencias. Valencia

- AVE Sants.Barcelona

- Centro Comercial Arena Multiespacio. Valencia

- Centro Comercial El Tiro. Murcia

- Centro Comercial Las Arenas. Barcelona

- Centro Comercial Vilella. Alzira. VALENCIA

- Nave VIDAL Alberique. Valencia

- Nudo Ferroviario de Mollet

- Nueva Terminal Aeropuerto de Alicante

- Nueva Terminal aeropuerto Malaga

- Rehabilitación Puente Purchena-Pulpí. Almeria

- Tramo AVE Villena - Sax

- Tuneles Delicias. Zaragoza

- Viaducto O Eixo del AVE Tramo Santiago Compostela - Ourense

Photo gallery

Installation

Depending upon the size, assemble manually with socket wrench or for quickest installation, use a standard air impact wrench. By following the instructions supplied with your order, tighten the screws until the heads twist off at a prescribed value. The force from the screws causes the rebar deformations to interlock within the coupler. The screws embed themselves into the rebar surface. This dual mechanical action results in a full positive connection for transferring tension or compression force from bar-to-bar.

Installation images

Quality Control

Tracción DOT Estándar AASHTD

- Compresión estándar AASHTD

- Selección DOT Alta Tracción

- Selección valor de Alargamiento DOT

- Ciclo elástico

- Esfuerzo reverso

- Selección DOT Fatiga

- Actuación Alta Fatiga

.jpg)

.jpg)